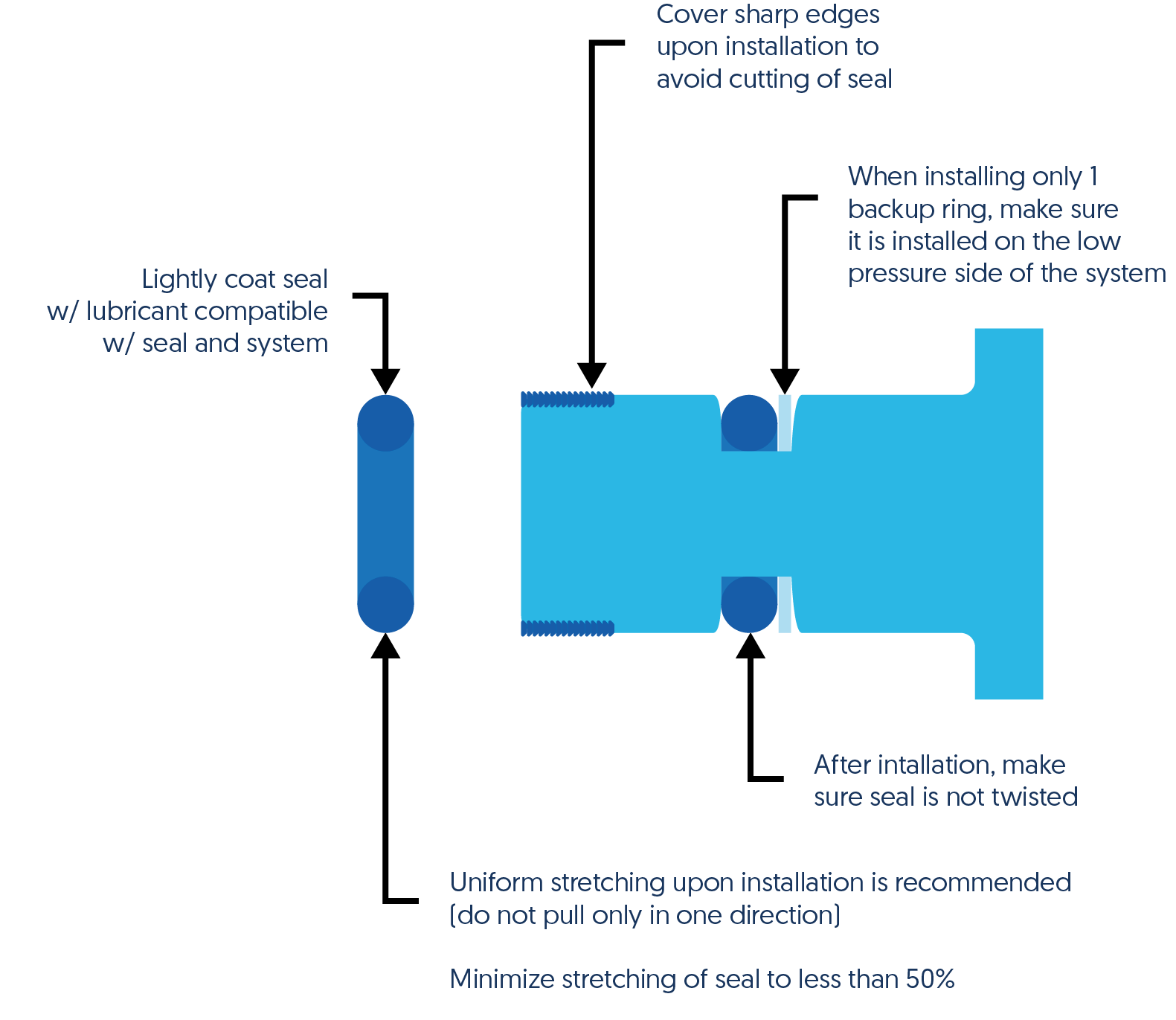

The oring seal design process begins with understanding the gland type in which the seal will be seated To ensure the oring fits properly it is recommended that the oring is stretched 1 to 5% circumferential, with ideal stretch at 2% Further considerations listed below include;Rubber Seals, Sealing Devices & ORing Seal Design Apple Gland Design, Oring and Other Elastomeric Seals, Static Applications AS5857 This SAE Aerospace Standard (AS) provides standardized gland (groove) design criteria and dimensions for elastomeric seal glands for static applications The glands have been specifically designed for applications using SAE AS568 size Orings at pressures exceeding

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

O-ring boss seal design

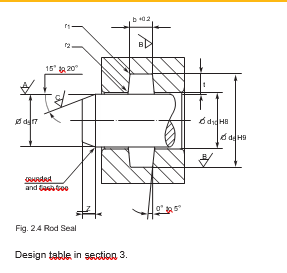

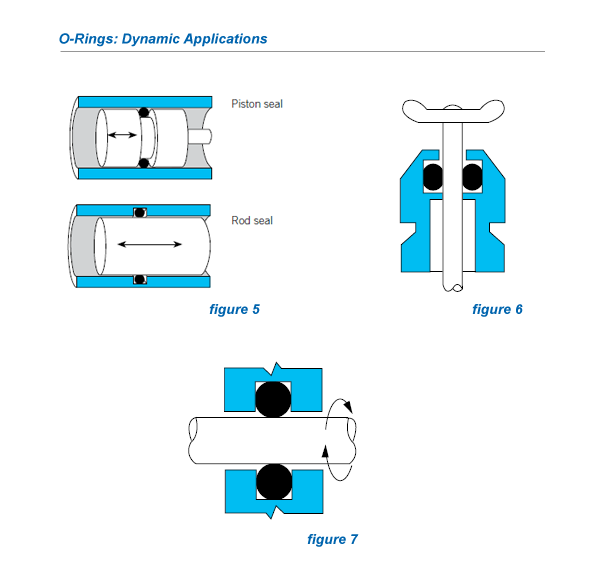

O-ring boss seal design- The profile of the T621 rod seal's NBR energizer ensures that the primary sealing lips maintain contact under low or nopressure conditions while ensuring proper sealing at higher pressures Challenges for Rod Seals Pistonrod seals require a different design because one side seals against the ambient environment Fluid leaking past the rodSeal gland type, sealing application (fluid, solid gas), pressures, operating temperatures, and chemical

O Ring Sizes And Dimensions Seal Design Inc

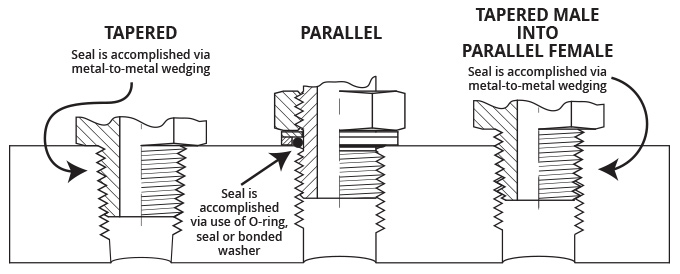

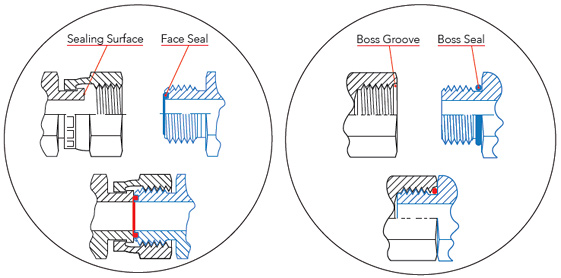

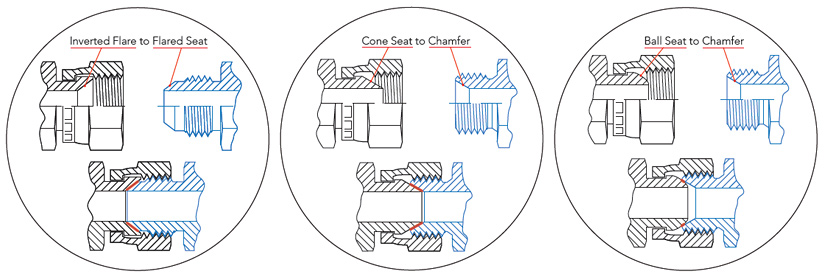

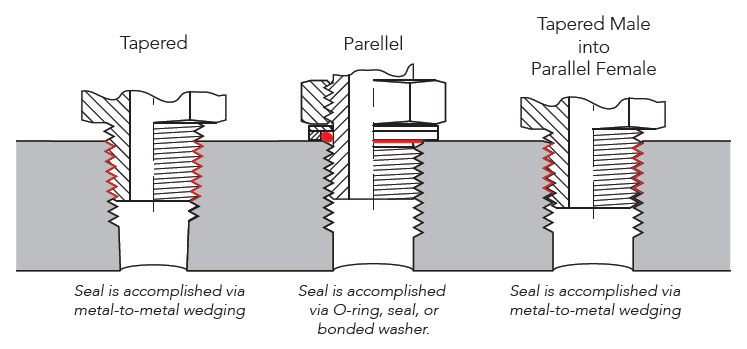

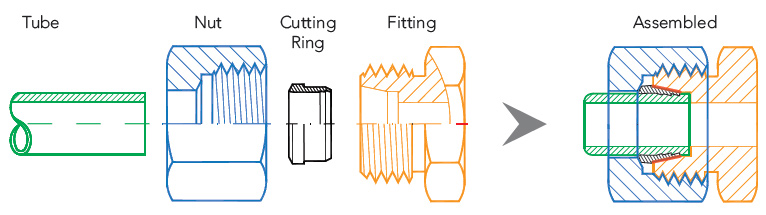

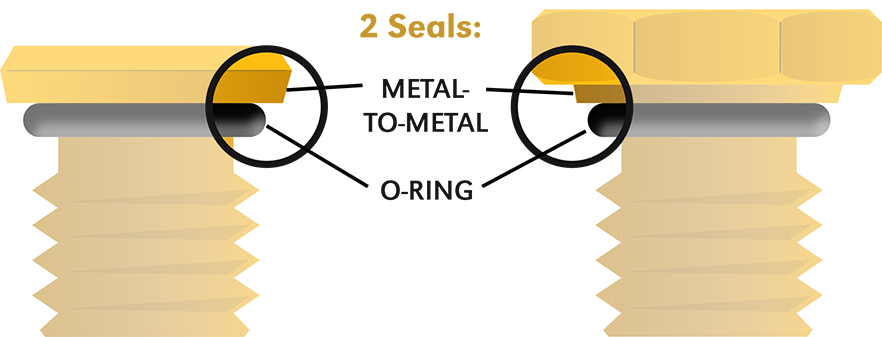

Oring Face Seal SAE Oring Boss HIAB Metric ISO 6141 Metric Chinese GB Face Seal Metal to Metal Sealing One of the rarer methods of sealing a fitting in port is Metal to Metal Sealing, also known as Cutting Face or Type B This design creates a seal by means of a sharp "cutting face" at the base of the male thread that cuts into the flats or "spotface" surrounding the port whenAn Oring is a torus, or doughnutshaped ring, generally molded from an elastomer, although Orings are also made from PTFE andThe Different Between O'Ring Boss and O'Ring Face Sealing SAE FittingsRG Group650 North State StreetYork, PA https//wwwrggroupcom/

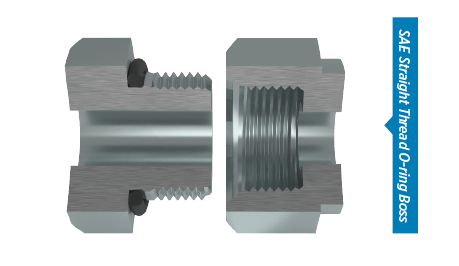

Contact Now AS568 JIS2401 British Stanrdad FKM FPM AED ORing HNBR AED O Ring Rubber Triangle Rings For High Pressure Valves Contact Now Hydraulic Rod Piston Seals Polyurethane Green Blue Yellow PU UCups, UNS/UHS Seal Profile Contact Now Hydraulic Step Seal,PTFE Step Rod Seal,Rod Step Seals,Rod and Piston Seals Contact NowOring face seal vs oring boss seal fittings difference Oring face seal vs oring boss seal fittings difference Oring face seal vs oring boss seal fittings difference Today Explore When autocomplete results are available use up and down arrows to review and enter to select Touch device users, explore by touch or with swipeAn oring boss seal is a technique for joining two fluidcarrying pipes, hoses, or tubing In an oring boss (abbreviated ORB) system, a malethreaded part is inserted into a femalethreaded part, providing a mechanical seal This system differs from others in that an additional nut is tightened over an oring into a chamfered area, creating a fluidtight seal This system is used most

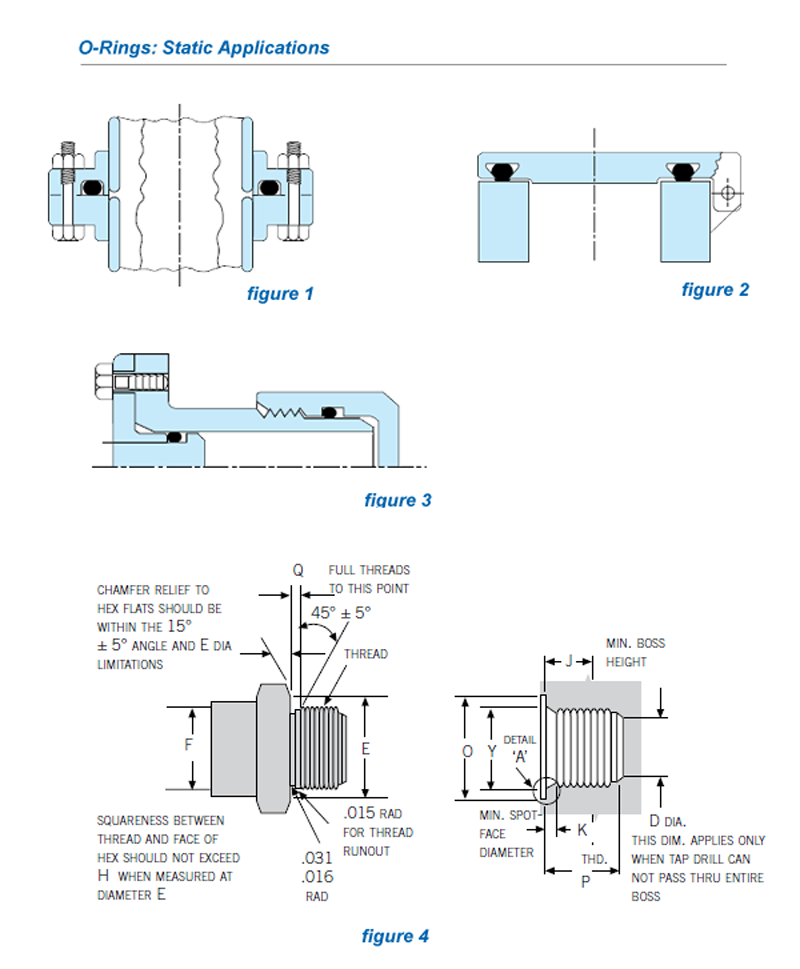

Boss Seals The AS5601 through 932 Oring sizes (Parker's 3 series) are intended to be used for sealing straight thread tube fittings in a boss The design charts below show the standard boss designs that are used for this purpose These charts list port dimensions per AS52 and J1926 and fitting ends per AS4395Call Us Seal & Design Canada Toronto, Ontario (416) Toll Free Headquarters Clarence, NY (716) Higbee Division Syracuse, NY (315) Email Us Seal & Design Canada Toronto, OntarioAll Seals is a world leader in supply of high quality orings, seals, engineered rubber and plastic products which serves the sealing needs of clients since 1958

Static O Ring Face Seal Groove Design Guide

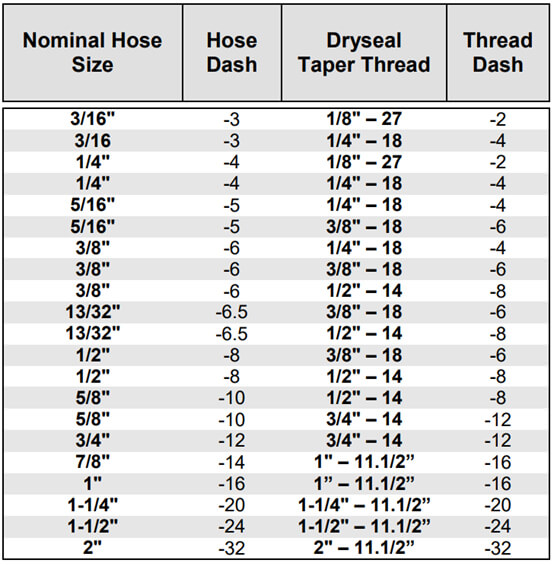

Will Tapered Thread Fittings Work In My Hydraulic System Hose Assembly Tips

FKM Orings #9 Hydraulic BOSSORB 11/4" Minimum 5 pcs Orings for Hydraulic SAE/BOSS Type Ends Used on or more commonly known as 11/4" Specifically on SAE/Boss/ORB Typically used with adapters or threaded plugs 90 Durometer FKM rubber Color Black Price is $037A boss sealis a seal in which an Oring is used for sealing a straightthread tube fitting on a boss or a port A boss is a cylindrical projection on a casting or forging The end of that projection is machined to provide a flat, smooth surface for sealing Tube fittings with parallel thread boss or port (ends) are made as per several standards Oring face seal is also called ORFS, as per SAE J1453 and ISO standard ORFS fittings have flat sealing surfaces that contain an embedded seal, which mates to flanged tubing or hose fittings Oring boss seal design is also called ORB as per ISO and SAE J standard

Seals Eastern End Cap O Ring Seal Design Guideline

O Ring Face Seal Vs O Ring Boss Seal Fittings Difference Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

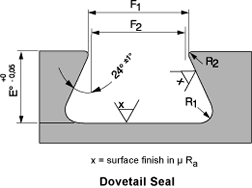

Oring groove design is a key consideration in the oring selection process Browse design considerations and recommendations for static face seals, metric orings, static dovetail orings, static rodpiston orings and dynamic rodpiston orings Once you find the right oring groove design you can easily order online from the world's largest oring inventory network The choice of FFOR or Oring boss types will depend upon individual designer preference based on application, wrench clearance, and fitting location All of the Oring type fittings offer superior sealing characteristics, as rated by Parker in the following categories Pressure Excellent;Static Axial Gland Design Application Gland Design for Static Application for Orings with Axial Squeeze Surface Finish X groove top and bottom for liquids X = 32 micro inches (08 μm Ra) for vacuum and gases X = 16 micro inches (04 μm Ra)

1

Newdealseals Com App Uploads 04 Newdealseals O Ring Handbook 14 Pdf

Contact Us Eastern Seals (UK) Ltd Unit 3 Sovereign Business Park Jubilee Industrial Estate, Ashington Northumberland, NE63 8UG, UK T 44 (0) 1670 F 44 (0) 1670 E sales@easternsealscouk Company No Vat No GB Linkedin;UltraChemicalResistant Kalrez 4079 ORingsfor Tube Fittings with StraightThread Connection Also known as Boss O rings, these Kalrez 4079 Orings are for use in tube fittings with a straightthread connection They're inherently softer and more compressible than PTFE Orings with comparable chemical resistanceORING KIT BOSS FITTING SEALS (9##) DESCRIPTION BOSS SEAL ORING SIZES, 212 TOTAL ORINGS PART NUMBER SKU Please choose a configuration from the list below in order to check availability and pricing If you require options not listed online yet, please click the Request a Custom Quote button below to request an offline quote

Www Applerubber Com Src Pdf Seal Design Guide Pdf

O Ring Info En O Ring Oring Handbook Eriks Sealingelements Technicalhandbook O Rings Glanddesigninformation Pdf

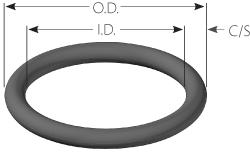

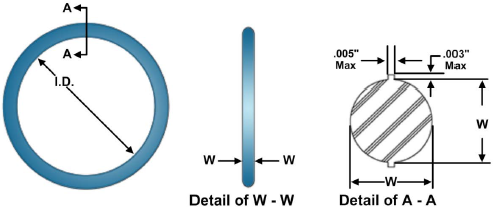

Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based on the following factors (refer to fig 123) Bore Diameter (A) Plug Diameter (H) Groove Diameter (B) Groove Width (F) as shown in the dimension tablesThose who are already familiar with Oring seal design may simply refer to the appropriate design tables for the information needed Even those who have designed many Oring seals may profi t by reviewing the basics from time to time 11 What is an ORing?A standard application for an Oring is sealing a tube fitting There are industry standards for boss fittings, with a series of Orings corresponding to each boss size AS4395 is a fitting end that corresponds with AS52 bosses Oring sizes are detailed in SAE J1926

O Ring Pressure Ratings Global O Ring And Seal

Hydraulic Fittings Types Qc Hydraulics

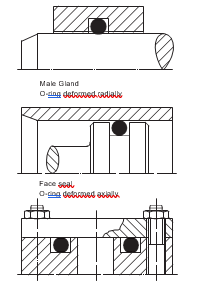

A third type of design is a boss seal You pretty much only see them on hydraulic fittings, but they have a lot of advantages for other applications In this configuration, the Oring sits in a triangular space that is usually made with a special form tool Boss seals are really easy to manufacture, since there aren't any undercuts, and if the gland gets damaged, they can beTemperatures, pressure, gas, or liquid contact, backup ring usage and surface finish Datwyler Sealing Solutions USA provides the basic oring static radial gland designDESIGN DIMENSIONS FOR ORING INSTALLATION Orings are normally used as seals in several ways, and dimensions of the groove or gland will also vary with the cross section of the ring, the type of operation, and the amount of pressure used in the system These dimensions will also be different if the Oring is sealing a liquid which has a low volume swell on the ring (015% Design

Why Is Leakage Still A Problem

Hydraulic Fitting Thread Chart Hydraulics Direct

Boss ORing Kit There is standard sizes for Orings used to seal straightthread tube fittings on a boss A boss Tube fitting with boss seal is cylindrical projection on a casting or forging The end of that projection is machined to provide a flat, smooth surface for sealingERIKS standard ORings and load them also into your created design info chemical volume swell (%) cross section diameter (mm) ISO 3601 free Calculate Results Reset calculatorO Ring Boss Seal Design on the face of it class 12 images one in a million people on a scale of 1 to 10 meme elf olympus xd picture card one off mind 意味 on a scale of 1 10 how will you evaluate your wellness and justify your answer one of the 意味 on the morning of june 14th 1968 a group of hippies on a scale of 1 to 10 how do you feel meme one piece pirate warriors 2 xbox 360 The

6 An Male Flare To 6 O Ring Boss Straight Cut O Ring Orb Fitting Black Orb Auto Performance Parts Metalfinishanddesign Auto Performance Fuel Systems

Diagram Of The Face Seal Design 1 Seal Ring Flexibly Attached 2 Seal Download Scientific Diagram

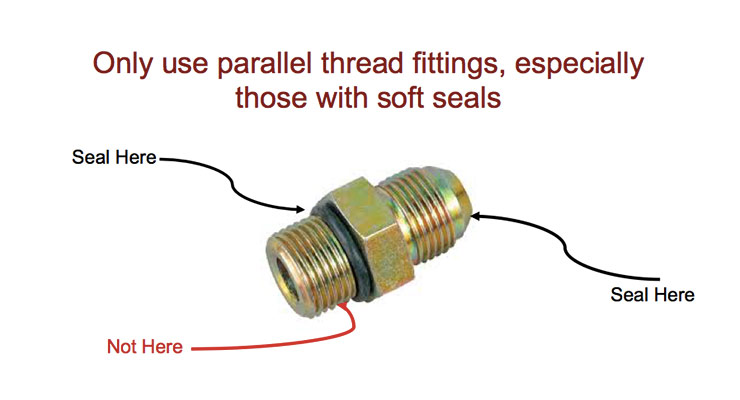

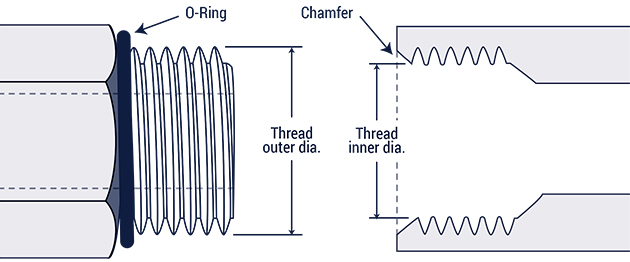

SAE Seal Design The SAE (Society of Automotive Engineers) oring boss seal uses a male fitting with an oring to seal in a female port with an angled section where the oring seats Unlike NPT seals that stretch the female portion, SAE seals use straight threads and therefore do not damage the mating part Applications This seal is popular in automotive applications and in other In an Oring boss system, a malethreaded part turns into a femalethreaded part to provide a mechanical seal In an ORB seal, an additional nut is tightened over the Oring into a chamfered area, creating a fluidtight seal The AS5601 through 932 Oring sizes are used for sealing straightthread tube fittings in a boss42 Static Male and Female ORing Seal Design Design Chart 42 and its accompanying Design Table 42 give one set of dimensions for static Oring seals when the confi guration is similar to a piston or rod application with no motion involved Aerospace Design Standard AS5857 is shown in Design Chart 41 and Design Table 41 for aerospace and military applications For applications

Sealing Devices And Materials Engineering Library

Static O Ring Guide Engineering Design Guide For Static Seals

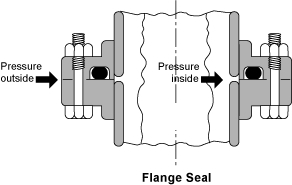

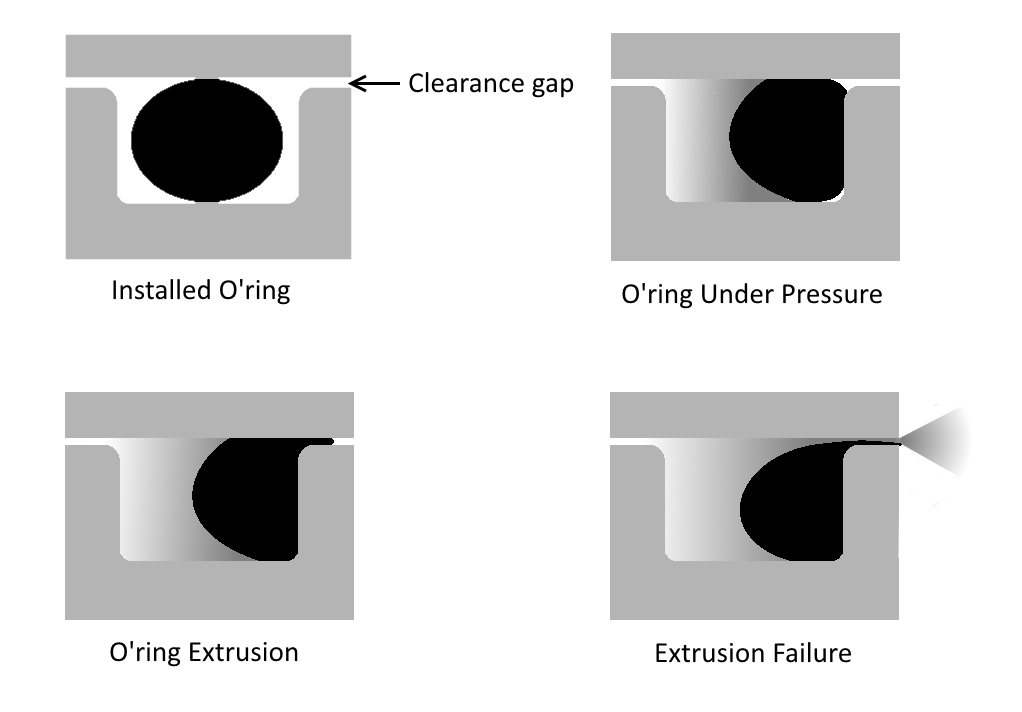

An oring boss seal is a technique for joining two fluidcarrying pipes, hoses, or tubingIn an oring boss (abbreviated ORB) system, a malethreaded part is inserted into a femalethreaded part, providing a mechanical seal This system differs from others in that an additional nut is tightened over an oring into a chamfered area, creating a fluidtight sealSTANDARD AS568B ORING GROOVE DESIGN The three main types of standard groove designs are Industrial Static, also called Radial, Industrial Reciprocating, also called Dynamic, and Face Seals also called Axial or Flange Radial and Dynamic seals require the presence of a diametrical clearance gap for installationThe engineering design guide provided by Ace Seal will help you navigate the wide range of static Oring applications used for sealing, including flange seal, radial seal, dovetail seal, boss seal and crush seal Contact Ace Seal regarding our static Orings engineering guide today

What Is An O Ring Introduction To O Rings Satori Seal

Www Applerubber Com Src Pdf Seal Design Guide Pdf

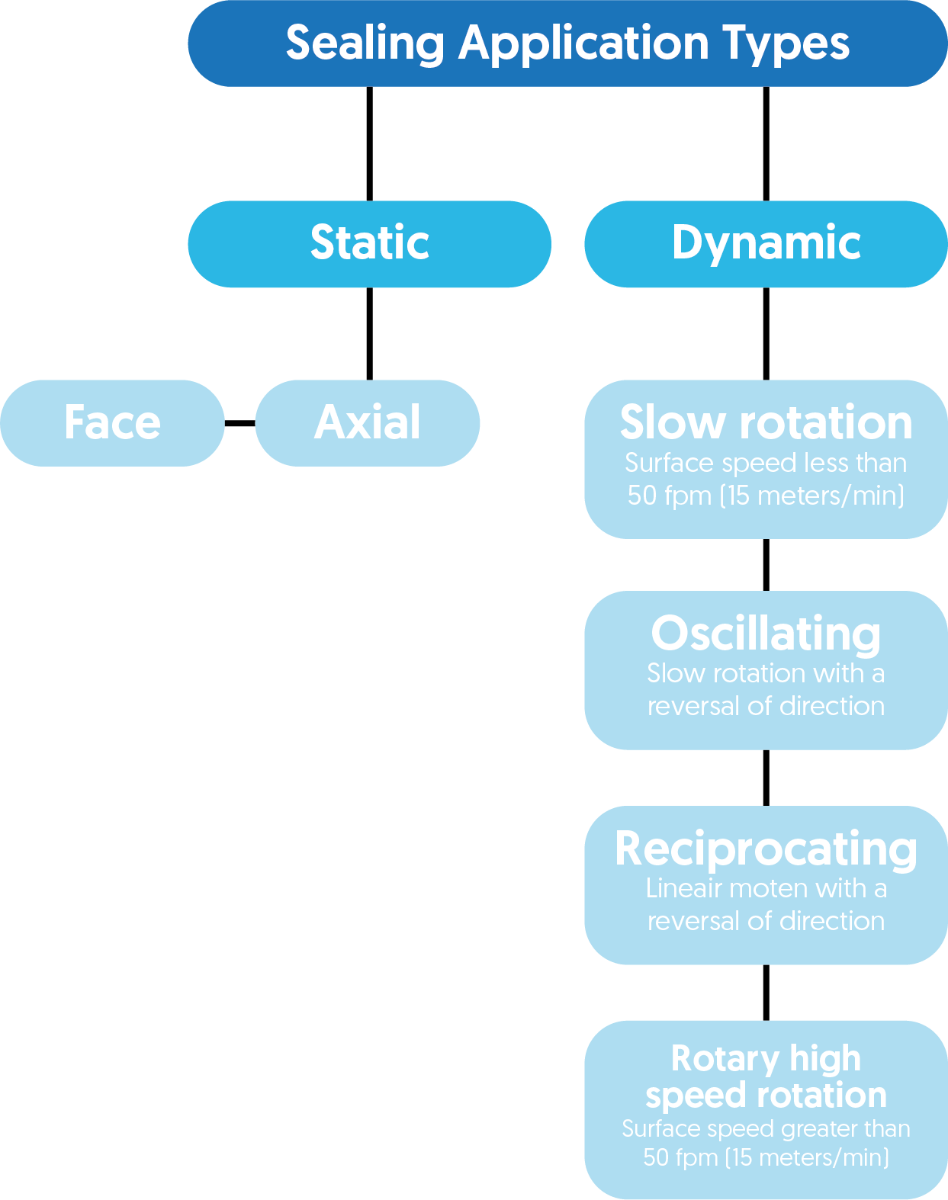

ORing Groove design plays an important part in how an oring seals Learn More > Contact World Class; Get ORing Boss Seal Design Background All the information in this documentation has been compiled Simplicity of construction, standOring Gland Design The following pages contain basic Oring gland design information Please contact the local ERIKS representative if an application does not clearly fall into these design parameters Static Applications There are five types of static Oring applications • Flange seal • Radial seal • Dovetail seal • Boss seal • Crush seal Flange Seal (Axial Seal) In flange seal

Jic 37 Flare Uno O Ring Boss Threads Ryco Hydraulics

O Ring Wikipedia

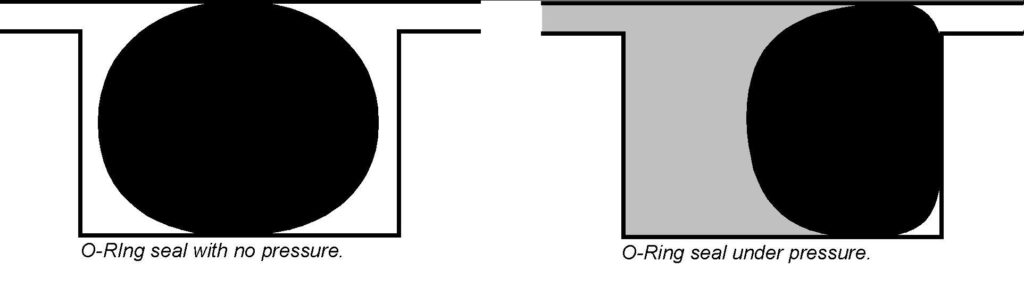

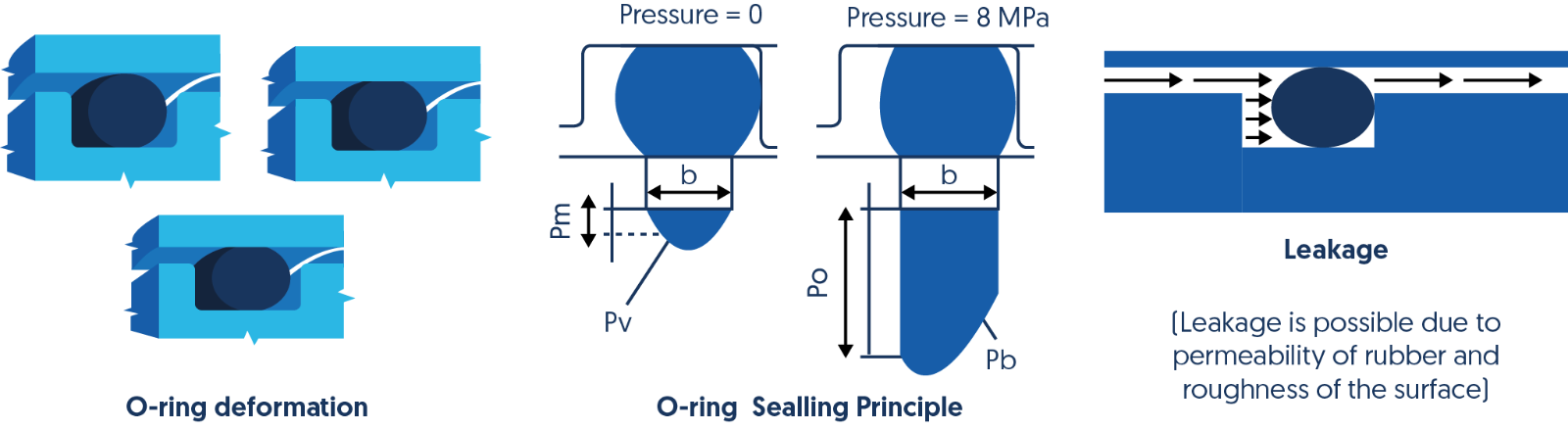

Oring boss (ORB) seals join two fluidcarrying pipes, hoses, or tubing In an Oring boss system a malethreaded part is inserted into a femalethreaded part, providing a mechanical seal In an ORB seal an additional nut is tightened over the Oring into a chamfered area, creating a fluidtight seal The AS5601 through 932 Oring sizes are used for sealing straight thread tube fittings inAn Oring is a solidrubber seal shaped like a doughnut or torus When compressed between mating surfaces, an Oring blocks the passage of liquids or gases Parco Orings are available in a wide range of standard and nonstandard sizes that are suitable for nearly all sealing applications Two dimensions describe the size of an Oring its inside diameter (ID) and its crosssectionalThis Oring seal design section will give you step by step instructions on how to design a seal or rubber part for your application Consider this a rubber guide or Oring guide in helping you find the exact rubber material and size you need Some parts of this online rubber or Oring design guide can be downloaded in PDF but everything can just be printed directly from our website for your

Boss 900 Series O Rings O Ring Boss Seals

Www Ttiinc Com Content Dam Ttiinc Products Pcn Honeywell Honeywell New Specifications Pcn mlh Pdf

Ease of Installation Excellent;Oring seal The tables at the right and the diagram below provide the recommended gland design parameters In addition, the gland surfaces must be free from all machining irregularities, and the gland edges should be smooth and true and free of nicks, scratches, and burrs A perfectly designed Oring seal is of little use if the OringORing Handbook Parker Hannifin ORing Diision Europe ORing Handbook Parker Hannifin ORing Diision Europe Preamble Sealing technology by ParkerPrädifa The Engineered Materials Group of the Parker Hannifin Corporation is the worldwide leader in the field of designing, developing and manufacturing sealing systems, vibration dampers, EMI shielding systems and heat

O Ring Sizes And Dimensions Seal Design Inc

O Ring Straight Thread Boss Sae J1926 1 Cpv Manufacturing

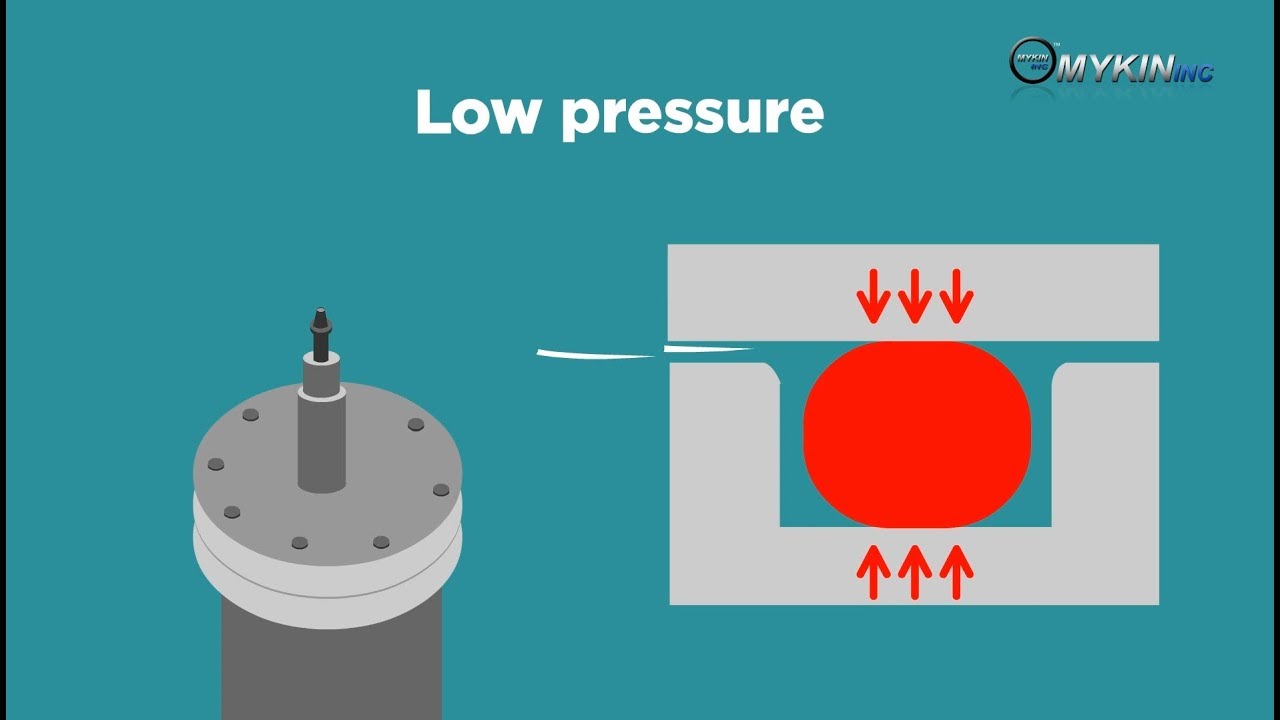

About US At Supaseal, we have a wealth of knowledge and experience in the Seal Industry, supplying ORings, Rotary Shaft Seals, Bonded Seals, Circlips and associated products We have expanded to cover four units at our premises in the Midlands, supplying customers in the UK, Europe, the US, Middle and Far East We pride ourselves on beingFor a highpressure seal to work to optimal levels, oring design and manufacture again depends on choosing specific materials for better performance under specific conditions Orings function on the principle that even pressure placed on the (more or less incompressible) oring material creates predictable deformation patterns around the perimeter of the gasket in its groove This meansThe squeeze or rate of compression is a major consideration in Oring seal design Elastomers may take up the stackup of tolerances of the unit and its memory maintains a sealed condition Orings with smaller cross sections are squeezed by a higher percentage to overcome the relatively higher groove dimension tolerances 3

Q Tbn And9gctbawdgmrvxzjukcpqcazhnof3nteuaiqhd99lcmwz5opexhzcd Usqp Cau

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

Not tapered, is used so that the oring seals under compression Because of their use in primarily high pressure applications, these seals are normally supplied in 90 durometer material AS568 No Tube Size (OD) Fractional Actual Dimensions ID Tol W Tol901 3/32 1/8 3/16 1/4 5/ ±005 056 ± 239 ±005 064 ± 301 ±005 064 ± 351 ±005 072 ±003The table on our detailed information page lists recommended dimensions for static radial oring glands by AS568A Oring dash numbers Orings and seals in static radial applications should consider the following;

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Seals

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Sealing Methods Adaptall

Applications Technology Sealing Elastomers In The Semiconductor Industry Are Used In Hundreds Of Applications Unique Environments Such As Vacuum And Plasma And Demanding Requirements For Contamination Place Great Importance On The

O Ring Sizes And Dimensions Seal Design Inc

O Rings 101 Understand The Seal Eology Page 4 Scubaboard

O Ring Groove Design Global O Ring And Seal

Static O Ring Guide Engineering Design Guide For Static Seals

O Ring Info En O Ring Technical handbook 14 eriks nv o Ring technical handbook o Ring gland design new Pdf

Sealing Methods Adaptall

Oring Ehandbook

Engineering Basics Guide To O Rings Eriks Shop Nl

Oring Ehandbook

O Ring Face Seal Vs O Ring Boss Seal Fittings Difference Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

Engineering Basics Guide To O Rings Eriks Shop Nl

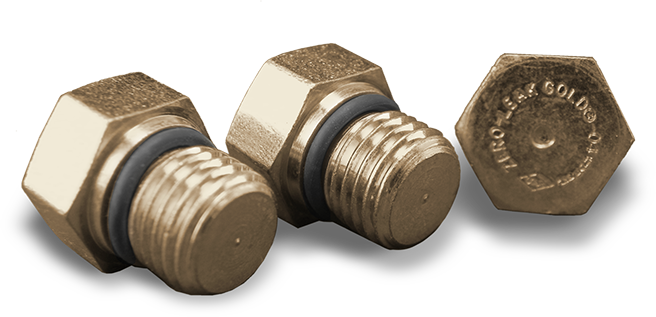

No Leak Sae J1926 Metric Iso 6149 Threaded Port Entry Plugs Zero Leak Gold

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Applications Technology Sealing Elastomers In The Semiconductor Industry Are Used In Hundreds Of Applications Unique Environments Such As Vacuum And Plasma And Demanding Requirements For Contamination Place Great Importance On The

O Ring Groove Design Global O Ring And Seal

Www Applerubber Com Src Pdf Seal Design Guide Pdf

Newdealseals Com App Uploads 04 Newdealseals O Ring Handbook 14 Pdf

Oring Ehandbook

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

O Ring Face Seal Vs O Ring Boss Seal Fittings Difference Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

Groove Design Gland Design O Ring Groove Gland Design

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

O Ring Face Seal Design Shefalitayal

Jic 37 Flare Uno O Ring Boss Threads Ryco Hydraulics

Jic Orb And Pushlock A Fitting Solution Wvo Designs

Applications Technology Sealing Elastomers In The Semiconductor Industry Are Used In Hundreds Of Applications Unique Environments Such As Vacuum And Plasma And Demanding Requirements For Contamination Place Great Importance On The

2 Design And Detail Information O Rings Stock O Ring Webshop

Eriks Technical Manual O Ring Gland Design Information Friction Extrusion

Hydraulic Fittings And Flanges Hydraulics Pneumatics

Engineering Basics Guide To O Rings Eriks Shop Nl

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

Oring Ehandbook

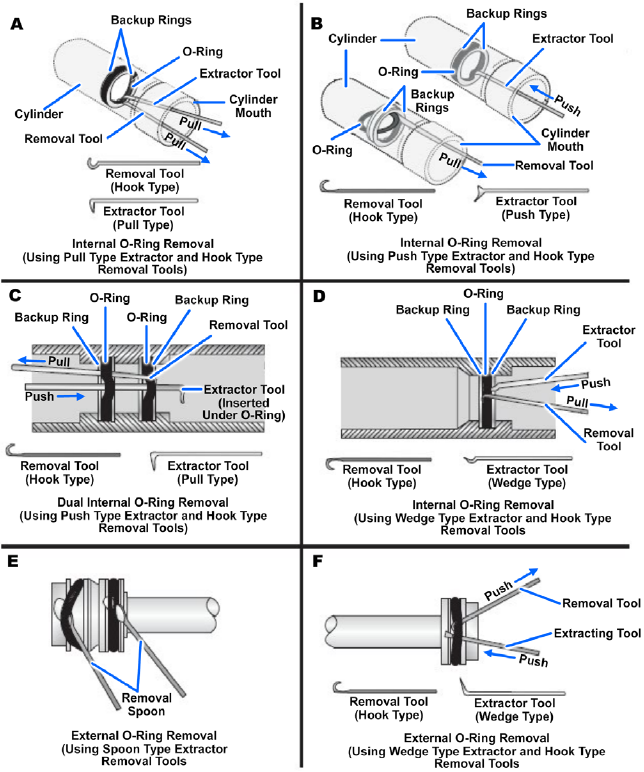

Aircraft Hydraulic System Seals Types And Installation Aircraft Systems

O Ring Groove Design Global O Ring And Seal

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

Sealing Methods Adaptall

G L Huyett Grease Fittings Catalog By G L Huyett Issuu

Www Eaton Com Ecm Groups Public Pub Eaton Hyd Documents Content Pct Pdf

O Ring Specialists Buy O Rings Silicone O Rings Seal Kits Gaskets Seal Polypak Rt Dygert

The Zero Leak Plug And Fitting Technology Incorporates A Corresponding Tapered Seal Surface

O Ring Groove Design Seal Design Inc

Oring Ehandbook

Ot Hydraulic Fittings Yesterday S Tractors

2 Design And Detail Information O Rings Stock O Ring Webshop

O Rings Encapsulated O Rings

.png)

Oring Ehandbook

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

Aircraft Hydraulic System Seals Types And Installation Aircraft Systems

Boss 900 Series O Rings O Ring Boss Seals

Eriks Nv O Ring Technical Handbook

1

O Ring Sizes And Dimensions Seal Design Inc

1

Sealing Methods Adaptall

Oring Ehandbook

Fittings 101 Orb Brennan Industries

O Ring Groove Design Global O Ring And Seal

O Ring Wikipedia

Aircraft Hydraulic System Seals Types And Installation Aircraft Systems

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Solidworks O Ring Placement In Groove Youtube

Www Applerubber Com Src Pdf Seal Design Guide Pdf

What Is An O Ring And How Does It Work Youtube

Sealing Devices And Materials Engineering Library

O Rings Encapsulated O Rings

O Rings Sealing Australia

No Leak Sae J1926 Metric Iso 6149 Threaded Port Entry Plugs Zero Leak Gold

O Ring Straight Thread Boss Sae J1926 1 Cpv Manufacturing

Boss 900 Series O Rings O Ring Boss Seals

Tee Adapter Orfs To Orb Fitting Fittings O Ring Seal Design

Static O Ring Face Seal Groove Design Guide

The Different Between O Ring Boss And O Ring Face Sealing Sae Fittings Youtube

O Ring Groove Design Global O Ring And Seal

0 件のコメント:

コメントを投稿